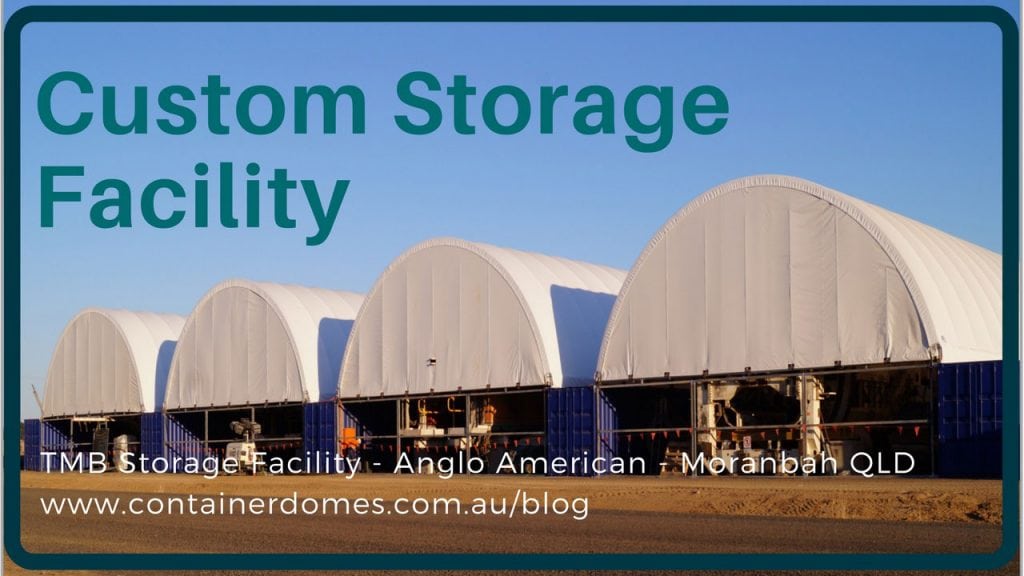

The CDA Team Design and Install a Custom Tunnel Borer Machine Storage Facility for Anglo American’s Moranbah, QLD Site.

Multi Shelter Container Dome Solution Case Study

The Scope of Works

Container Domes Australia designed, fabricated and installed a series of custom sized Container Domes to be used to protect a Tunnel Borer Machine (TBM) while it is being stored at the client’s Moranbah site.

The four Container Domes were each 14m wide x 42.7m long x 8.6m in the apex when mounted on standard high cube containers and included Half End Walls with company branding. The Container Domes provide the perfect weather protection for the TBM, and the containers are also being used to store sensitive parts of the machine.

The Challenges

Our Installation Team had to locate and secure the containers first, wait for the TBM to arrive and the pieces located in their allocated area and then install the Container Domes and Half End Walls over the top.

Leading the way in On-Site Shelter SolutionsLet our friendly and professional Sales Team help to find the perfect Shelter Solution for your Site.

The Outcome

CDA was able to meet the very high safety requirements set out by our client. Our Installation Team was able to work with and around various other contractors on site with cohesion and can report that zero safety incident occurred throughout the project.

Want Something Different?

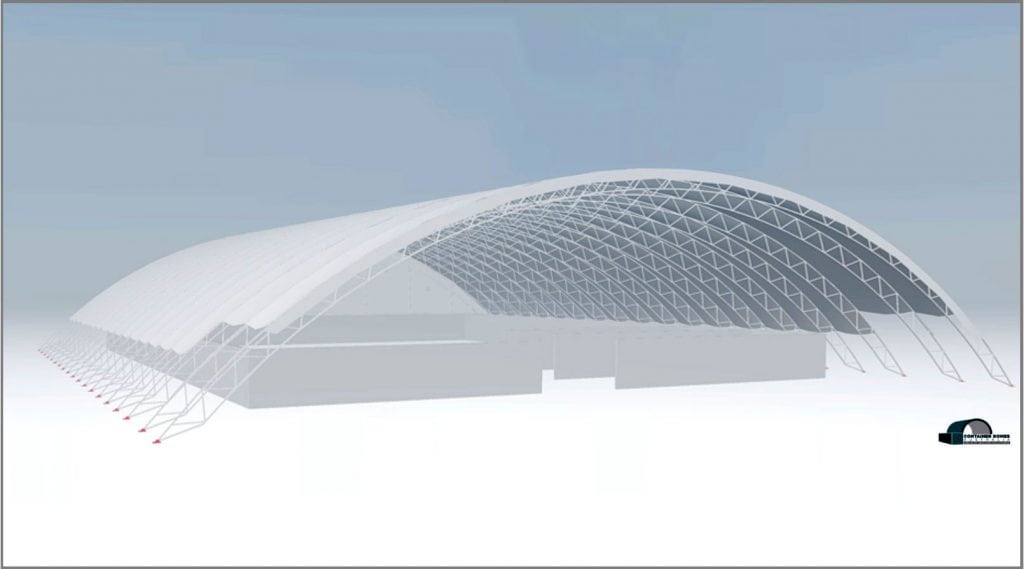

Looking for a Custom Designed Shelter for your Site? Let the Team at Container Domes Australia create a Container Dome set-up for you with your specific On-Site requirements in mind.

We work with our clients every step of the way, from concept to certification and installation, to ensure your project is completed on time and on budget.

We are so confident in the quality of our work that each Container Dome is backed by our full 10-year structural warranty on both the frame and cover giving you complete peace of mind.

From single shelter set-ups to multi-shelter turnkey projects, Container Domes Australia is Leading the way in On-Site Shelter Solutions.

Our Container Domes are made using high-quality materials from trusted, Australian brands. All welds are in accordance with Australian Standard AS/NZS 1554.1 and each shelter is certified to Level of Importance 2, Terrain Category 2, for your individual wind region.

Need To Be Sure?

We work with our customers every step of the way to ensure we find the perfect solution to your On-Site Shelter needs. Our Range of Container Dome and ContainerSheds have been designed and manufactured to the highest of Australian Standards to give you complete peace of mind.

All Shelters are designed and manufactured in Australia.

We offer a 10-year structural warranty on the frame and cover.

We are ISO Certified (Quality and Safety).

We have our own ticketed install service (QBCC Builders Licence No: 1283775).

I am extremely satisfied with the install process and the finished product. I wish all projects went this smoothly!